5 Unsettling Lessons About Airplanes I Learned Making Them

Flying might be one of the safest ways to travel, but that doesn't mean it makes a lick of goddamn sense. How does a 500-ton airplane just stay up in the air like that? If it's not wizards, we don't know the answer. Luckily we found somebody who does: "Lisa" actually makes jet engine parts at one of the largest aerospace manufacturing facilities in the world, and she had basically nothing comforting to say ...

Whenever A Plane Crashes Anywhere In The World, We Automatically Assume It's Our Fault

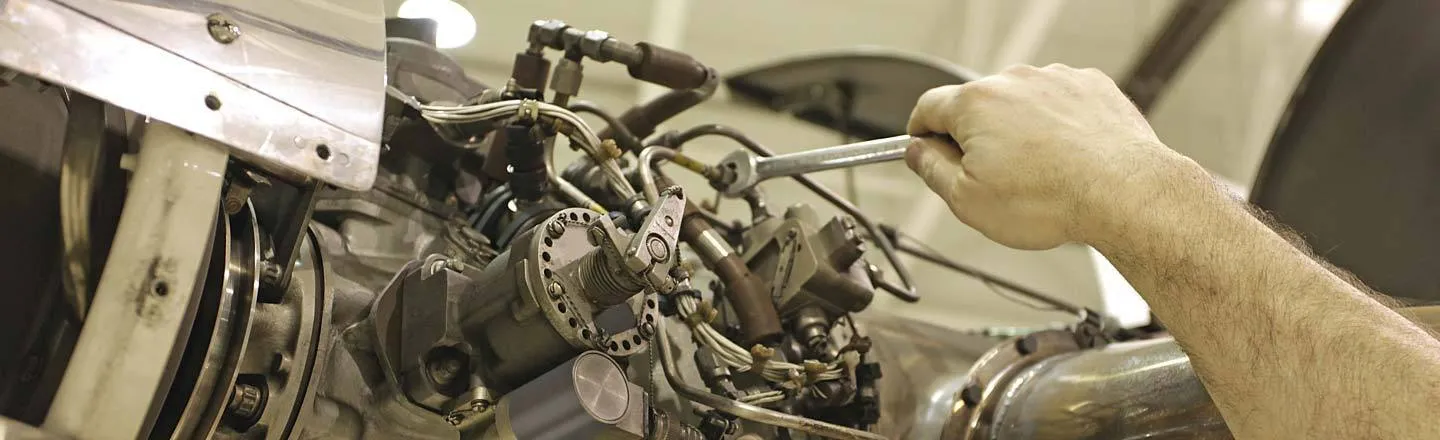

How many people would die if you screwed up at your job? Hopefully that answer is "zero" or at least "less than 300." No such luck when you're an engine-part manufacturer:

"I machine parts that are primarily used in commercial and military aircraft," Lisa explains. "My specific responsibilities are to make sure the oil levels and voltages are all in the proper place and produce parts that fall within spec of the print, etc. If I forget to turn off my machine while I go pee or something, I end up making a faulty part or kill 300 people in a fiery plane crash."

"I have soiled so many underpants to keep you safe."

Of course, Lisa does everything to make sure her engine components are 100 percent good to go, but she still loses sleep sometimes wondering if she forgot to check a vital dimension on one part in an order of 250. And when your products are used by major commercial airlines, whenever a plane falls out of the sky, you inevitably end up doing a gritty Urkel impression by tearfully asking yourself: "D- ... did I do that?!"

"When the Germanwings flight crashed in the French Alps in March 2015, killing 150 people on board, I panicked all damn day until I heard it was actually caused by the co-pilot. You want to know why? Because I make parts for that model of airplane." According to Lisa, all this stress messes with your mind until you actually start "praying that if a plane goes down, it was human error or negligence."

"Please be sky gnomes, please be sky gnomes ... "

Those probably feel like some pretty messed-up prayers at the time, but it's an understandable urge. Think about it:

"Now, we don't make parts for the Malaysia Airlines planes," Lisa says, "but you best believe I was sweating bullets until I found that out for sure." If you want to know how that feels, imagine reading a headline that says "Hundreds Of Deaths Blamed On Local Office Idiot Clicking Wrong Button In Email Program." Until that name is confirmed, you're probably going to be losing some sleep ...

A Pinch Of Salt Or The Wrong Soap Can Blow Up An Airplane's Engine

You probably assume, or at least desperately pray, that jet engines are nigh-invincible machines. You would be horrifically wrong:

"Let's say I take my break and have a quick bag of Lay's chips," Lisa explains. "Then, let's say I neglected to wash my hands after. The salt left over from the chips would cling to my fingers and then be transferred onto the parts, which can cause corrosion." Now, this won't cause an immediate problem, but remember that mechanical parts need to be regularly maintained and replaced due to normal wear and tear. If a part gets eaten away by salt, then it isn't going to hold up as long as a well-made part would, and it could crack mid-flight before the next scheduled check-up.

We're never opening a bag of these again.

"Depending on the part, that could cause engine failure or explosion," Lisa informs us, after which we thanked her as sarcastically as possible. Unfortunately, this only encouraged her to tell us more:

"Welding is a huge factor in these parts. There are stringent checks to make sure that a part has been welded enough, but if a faulty one got through, that part could also crack apart during flight and cause a crash for sure." That can also be achieved by washing the parts in the wrong cleaning agent. That's right: The wrong kind of soap can also cause the engine to corrode, ultimately leading to early reduction in performance and hundreds of your fellow passengers suddenly finding religion.

Soap bubbles are an act of God.

People Bleed On The Parts All The Time

"I can't explain how much blood has touched the parts that we make," Lisa tells us. Which, after finding out that salt downs planes, didn't comfort us much.

"Personally, I've been cut in the machine countless times, some of which were very deep. If a drop of blood gets into the oil in the bottom of our machine, we are supposed to stop production, drain out the contaminated oil, and put new oil in. However, it's rare to be able to tell if you bleed into the machine."

The machine hungers. It takes what it wants.

Lisa goes on: "I've handled loads of parts before without knowing I was bleeding. Even something as small as a chicken tongue (that stupid piece of loose skin by your nail that bleeds when you pull it) can get blood on your part without you noticing. ... I guarantee almost every machinist has gotten blood on their parts. The parts do get cleaned after the machining process and that's usually when it gets caught, but there have been times where it got as far as inspection."

So that's what keeps airplanes aloft -- blood sacrifices!

But it makes them a target for cloud bears.

Potentially Lethal Mistakes Are Unavoidable

Printer paper is about .004 of an inch thick, while a strand of hair is around .003 of an inch. Lisa's plant, on the other hand, has to get their parts' measurements down to within .0001 of an inch or risk turning their clients' passengers into smoldering piles of ash barely an inch high.

"Not to scare anyone," Lisa lies, "but there is a human behind every tiny piece that goes into the engine that you are looking at out of your airplane window, and humans make mistakes."

"Actually, this one was on the robot arm. He's been distracted; trouble at home with the vending machine."

"There is a specific system in place to catch any bad parts, but that system isn't perfect. When I'm done with my order (an average of 100 parts), they get cleaned and then sent to an inspector. This inspector does a lot check, which means they pick out about 20 parts out of 100 and only check them." We aren't mathematicians or anything, but that still leaves approximately too damn many potentially faulty engine parts in the mix.

Lisa continues (to scare the crap out of us): "If they find a mistake, they have to 100 percent check all the other parts in your order." There's always the possibility that someone fucks up and the parts get passed, either because of an honest mistake or an inspector wanted to go home early and catch that Lost rerun.

Season 3, episode 1.

"Recently, I had a dimension that was ridiculously hard to check, and the inspector and I kept measuring it close but still couldn't confirm it. Eventually, the inspector got so frustrated trying to check it that she just up and called it good. I immediately stopped the process at that point, but mistakes like that have been known to happen."

The People Being Hired To Make Airplane Parts Don't Necessarily Need To Be Qualified

It takes a lot to work at a jet engine manufacturing plant: patience, attention to detail, the ability to deal with the mind-bending stress without becoming an alcoholic. You'll notice that we didn't mention anything about advanced certifications or a college degree. Lisa explains why:

"I had no machining experience before applying, and math and science were my worst subjects in school. That didn't matter, though, because the only job requirement is a high school diploma or equivalent. New inspectors that aren't sure how to measure something might just say that it's OK because they don't want to look like they don't know what they are doing. I will ask them, 'OK, but did you check this?' and they will blatantly lie to my face because they are lazy. Luckily, we get rid of them pretty quick, but the people with seniority that mess around, they don't get the boot because we are desperate for bodies running machines."

"He, uh, gave me this instead of a resume."

"Hired."

But, still, inexperience can be forgiven, right? Who hasn't had a nervous first few weeks at a new job? Wait, no, it absolutely cannot be forgiven when your job is defying nature to keep planes flying. But it's not as bad as straight-up incompetence.

"I've seen people fall asleep on the job while their machine is running," Lisa says. "Plus, people fail their welding re-certification tests all the time. You have to send in pieces of your welding work to be examined, and if they fail, you have to think that person made bad parts before."

"Nah, I was just drunk that day. No need to worry."

So ... does anyone know if Amtrak gives you discounts on bulk ticket purchases? We suddenly feel like making them a very rich company.

Cezary Jan Strusiewicz is a Cracked columnist, interviewer, and editor. Contact him at c.j.strusiewicz@gmail.com.

Psst ... want to give us feedback on the super-secret beta launch of the upcoming Cracked spinoff site, Braindrop? Well, simply follow us behind this curtain. Or, you know, click here: Braindrop.

For more insider perspectives, check out 5 Reasons Flying a Fighter Jet Is Way Crazier Than 'Top Gun' and Fast & Furious Is Full Of It: 5 Racecar Driver Realities.

Subscribe to our YouTube channel, and check out Why The 'Firefly' Crew Were The Bad Guys, and watch other videos you won't see on the site!

Also, follow us on Facebook, because we want to follow you everywhere.

Did you know cats modeled their "meow" after the cries of human babies, just because they knew us humans care about that noise? Did you know dogs can read your mind (emotionally), and live in constant suspicion that you know where the good food is (you totally do)? In the next LIVE episode of the Cracked Podcast, host Jack O'Brien leads Cracked's team of pet-loving/fearing comedians through all the ways our dogs and cats are more powerful, creepy, and awesome than we ever could have imagined. Jack will be joined by Carmen Angelica, Dan O'Brien, Alex Schmidt, and Jake Weisman at the UCB Sunset Theatre on Wednesday, March 9, at 7 p.m. Purchase your tickets here!

Have a story to share with Cracked? Email us here.